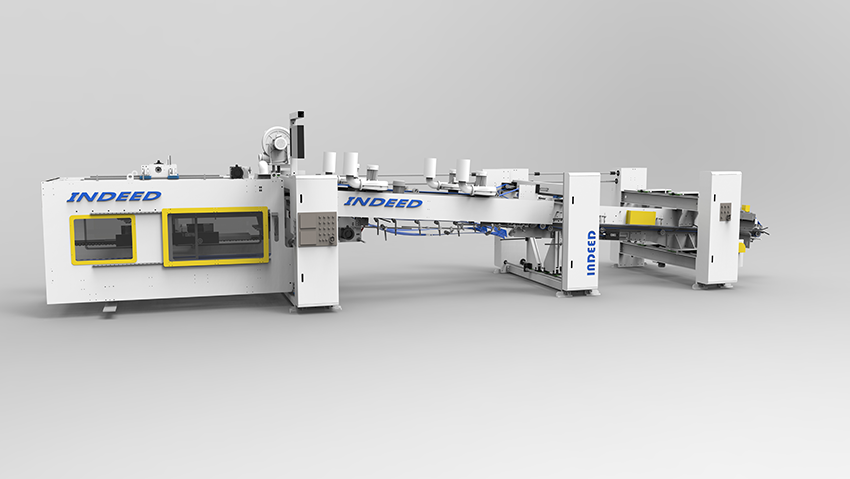

滚胶ROLLING GLUER

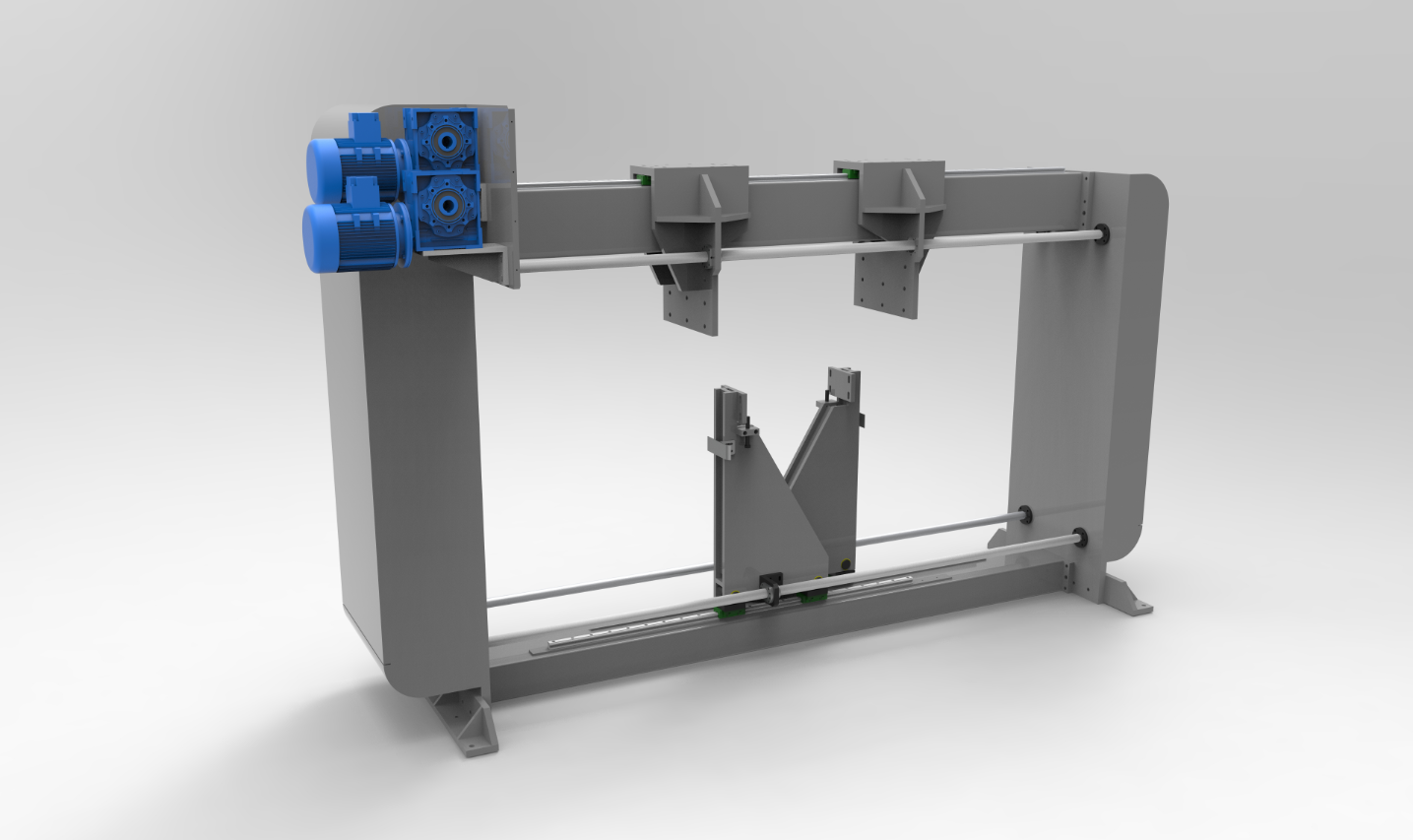

①折梁中部有90°整形轮,控制折弯精度

THE MIDDLE OF FOLDING BEAM,THERE’S CORRECT WHEEL TO CONTROL THE FOLDING ANGLE

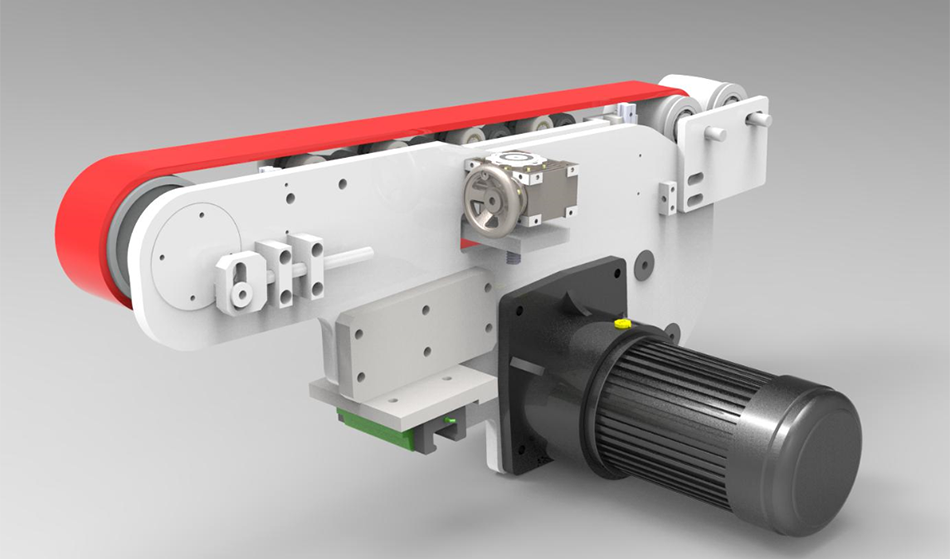

②下皮带通过减速机控制可单独控制速度差,用以矫正纸板剪刀差

LOWER BELT THROUGH MOTOR CONTROL THE SPEED DIFFERENCE,TO CORRECT THE SCISSORS DIFFERENTIAL.

③每一个梁侧都有正确的车轮,以确保纸板成型

EVERY BEAM SIDE HAS CORRECT WHEEL,TO ENSURE CARDBOARD SHAPING

④中间龙门结构,更好的改善折梁在高速运行时的稳定性。

GANTRY STRUCTURE,TO ENSURE HIS STABLE WHEN HIGH SPEED RUNNING

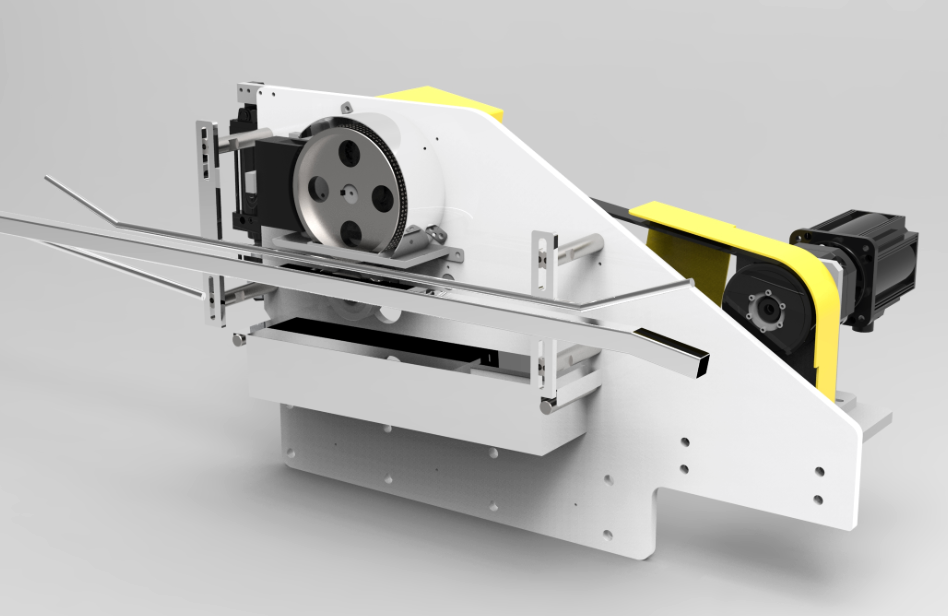

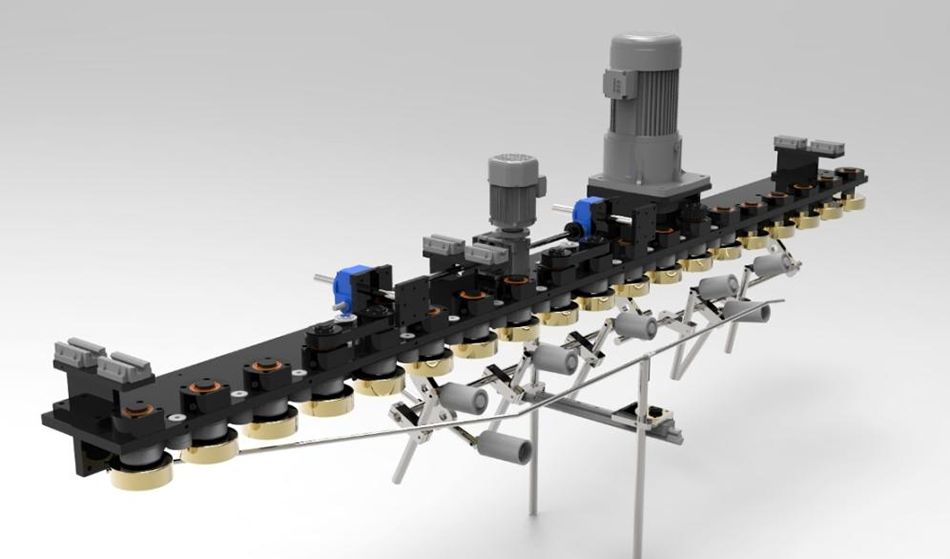

①全伺服控制在高速运行时完成精确计数,堆码和排出

ALL SEVER MOTOR CONTROL HIGH SPEED RUNNING TO ACHIVE COUNTING ACCURATE, CARTON OUTPUT

②预压风机可随时调整方向,强大风压防止纸板向上弯曲

ADJUST WIND PRESSURE AT ANY TIME ,TO AVOID BOX CURVING

注:产品的参数变动和机构改良,恕不另行通知。

昆山英立德机械有限公司 | KUNSHAN INDEED MACHINE CO.,LTD

地址:昆山市周市镇东辉路113号

联线人电话:陆女士 +8618068087910

邮箱:bobbylu@indeedmachine.com 、 asmlei@indeedmachine.com

联线人微信